Computerized Precision Pendulum

Randall D. Peters1 and Eric Daine2

1Physics Department, and 2 School of Engineering, Mercer

University, Macon, GA.

Copyright May 2012

Abstract

A precision pendulum with two fixed axes, each having a period close to 1

s, has been outfitted with a small fully differential electronics package

using a capacitive sensor. Power is received through the USB cable of the

computer, which operates with a 24-bit analog to digital converter sampling

the pendulum's motion at a frequency near 50 Hz. A user friendly software

package provides real-time graphical display of the pendulum's free decay.

Records stored in computer memory are available for later detailed investigation

by a variety of analytic means.

Background

The heart of the instrument used for this study is the Kater pendulum sold

commercially by Tel-Atomic Inc. [1], and which was described in a ``Physics

Teacher'' article [2]. Apart from a research-oriented activity [3], it has

only been previously monitored with timers used to measure its period.

Typically the earth's gravitational field is measured with a pendulum using

only a stopwatch (manually) or a period counter (electronically). Although

the latter is more accurate than the former, both methods are primitive as

compared to the results that can be achieved with a sensor that monitors

full motion of the pendulum [4]. Such a sensor was used for the study [3];

however, the electronics employed for that work is of a type that is no longer

commercially available. The NE5521n chip that was the key component used

in conjunction with the fully differential capacitive sensor [5] ceased to

be readily available after a factory fire. Fortunately, not long afterwards,

Analog Devices marketed its capacitance to digital converter (AD7745), which

is used in the sensor package of the present work. It is also employed in

the computerized Cavendish balance [6], another instrument that was designed

by the first author of the present article. Its use of two capacitive sensors

to monitor boom motion allows for a `mechanical common mode rejection' that

makes it more user-friendly than traditional Cavendish experiments based

on optical sensing.

Instrument

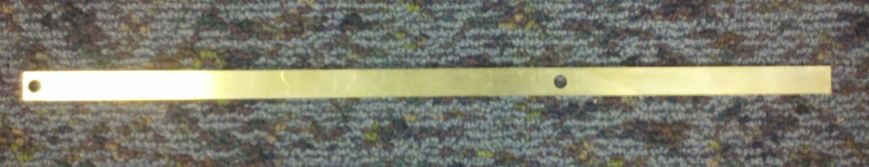

Shown in Fig. 1 is a photograph of the brass bar pendulum.

Figure 1. Rotation axes are provided by hanging the bar on a `knife

edge' that is visible in Fig. 2. For `end axis' oscillation, the hole close

to the end of the bar is used. For `mid axis' oscillation, the other hole

is employed. The bar was computer-designed to yield an approximate 1 s period

for each of the two axes.

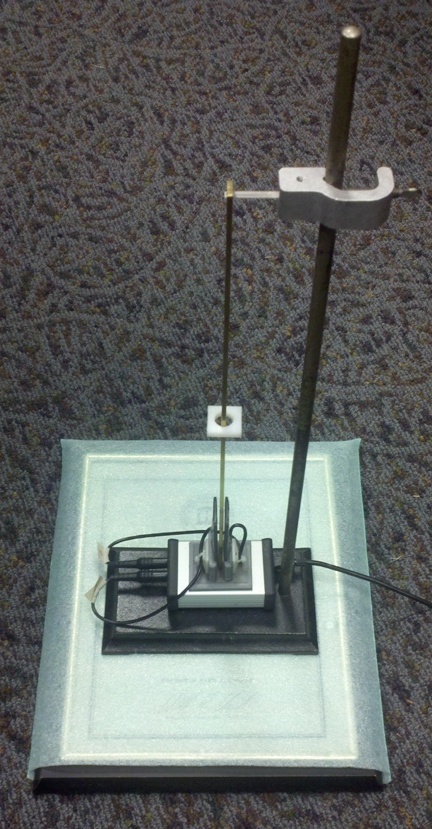

Figure 2 shows the pendulum configured to swing about the end-axis.

Figure 2. Seen mounted on the pendulum is a small square nylon mass

whose position on the pendulum is adjustable. This sliding mass is used in

the method for estimating `little g' most accurately, and which is described

later in detail, in the context of some representative data.

Estimates of g (approx 9.8 m/s2) require that data be collected

using both axes. For operation about the mid axis, the clamp seen near the

top of the Fig. 2 picture would be repositioned on the vertical steel rod.

It would be a lower clamped position for which the end hole is made to swing

along an arc that is below the position of the active elements of the capacitive

sensor electrodes. The electrodes are not visible, since their pc boards

have been wrapped with heat shrinkable plastic to avoid any shorting of the

electronics that might happen if the brass pendulum should come into contact

with them through misalignment. The whole electronics package is pictured

in more detail in Fig. 3.

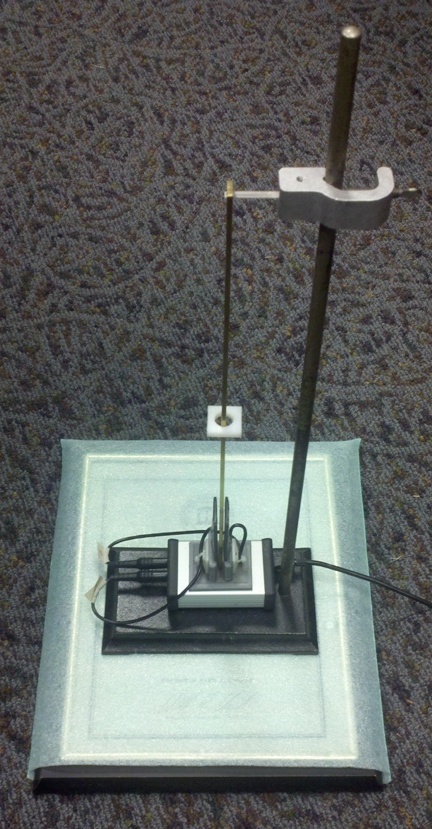

Figure 3. Closeup photograph of the electronics. The top clamp is

positioned for a clearance of about half a cm between the bar end and the

bottom plastic piece sitting on top of the aluminum box that houses the

electronics.

Representative data obtainable with the pendulum

The package is readily configured to operate with any of the most common

computer systems, whether Windows or Linux software, and hardware that is

either 32-bit or 64-bit. Data of the present article were obtained with an

XP laptop operating with a 32-bit cpu.

Shown in Fig. 4 are some long-term free-decays involving oscillation about

both axes.

Figure 4. Free-decays showing exponential fits to the positive turning

points. The fits were computed with Excel, but the total number of points

at 60,000 is too large for graphing with Excel. The graphs were generated

using Mathematica.

To obtain a given free decay the pendulum was set into motion manually, by

pushing on the bar with a finger resting on top of the sensor electrodes.

It is seen from Fig. 4 that energy dissipation of the pendulum is more

complicated than simple viscous damping. The Reynolds number is initially

large enough for air drag to involve a quadratic term in the velocity. Thus,

except at the start and end points, it causes the record to dip below the

exponential. The deviation is seen to be greater for end axis oscillation

than for mid axis oscillation. The quality factors also differ, being larger

at 1800 for the former and 1500 for the latter. These numbers are only

approximate, since Q is amplitude dependent except for viscous damping [7].

Textbooks routinely give the impression that a damping correction must be

generally applied to an estimate for the period of a mechanical oscillator.

In other words, when the equation of motion is of the form

|

..

x

|

+ 2 b |

.

x

|

+ w02 x

= 0 |

|

(1) |

involving a viscous (linear) damping parameter b,

the period of oscillation is given by

| T =

2p/w ,

w =

[w02-b2]1/2 , b =

w0/(2Q) |

|

(2) |

It is difficult to experimentally verify the damping redshift predicted

theoretically by this equation. As seen from the following log-log graph,

it amounts to less than one part in 10 million for the present experiments,

where Q > 1000.

Figure 5. Fractional value of the damping

redshift|(f - f0)/f0| plotted as a function

of the quality factor.

For efforts to estimate the earth's field to one part in ten thousand, there

is clearly no need to worry about the complications of Eq.(2).

Measurement Technique

As with the technique used in ref. 4, we here choose to work with Lissajous

figures, and two examples are provided in Fig. 6.

Figure 6. Illustration of the method used to obtain a theoretical

fit to the data. Only 4 seconds are shown in the time plots, of the 88 s

total time recorded. All 4400 points were included in the generation of the

Lissajous figures.

The frequency measurement is determined by the sample rate of the electronics,

which was measured to be 49.93 Hz. Although this number of acquired samples

per second is somewhat variable and temperature dependent, a change of about

50 Celsius degrees is required for an increase in the frequency of one part

per thousand. Based on the authors' experience with the package, it is expected

that the oscillator in the electronics that is responsible for this sample

rate should be stable to a few parts per ten thousand for the typical laboratory

environment.

For accurate estimates of g the frequency needs to be checked carefully the

first time and maybe periodically thereafter. It is readily done using a

quartz-based stopwatch or by comparison with the NIST standard wwv. An equivalent

to the latter (radio broadcast signal) can be monitored via the internet.

By comparing the two for a total time of 5 to 10 minutes, the sample rate

can be measured to a part per ten thosand; the objective sought in estimates

of the earth's field when measured with this Kater pendulum.

The beauty of the Kater method is the following. If the periods about the

two axes can be matched, then the instrument is equivalent to a simple pendulum

whose length equals the distance between the axes; which for the Tel-Atomic

unit is 0.2481 m. If they are `slightly' different, then the following equation

can be used to estimate g in m/s2 typically to a few parts per

thousand:

| g =

4 p2 × 0.2481 × |

Tmid

Tend3

|

|

|

(3) |

To thus use Eq.(3) the mid axis oscillation that was recorded yielded the

graphs of Fig. 7.

Figure 7. As with the bottom set of Fig. 6 but oscillating about the

mid axis. The estimated frequency for this case (based on the theoretical

parameter yielding a match) was 1.0016 Hz.

Based on the frequencies indicated in Figures 6 and 7, one obtains from Eq.(3)

an estimate of g = 9.77 m/s2. We will see from

the data presented later, obtained with a small mass slider whose position

on the bar is adjustable-that for differences as small as typically encountered

with the Tel-Atomic Kater pendulum-a better estimate for g is possible. It

is obtained by using g =

4 pi2 L (Tmid/Tend3 + 1/ Tmean2)/2,

where L = 0.2481 m and Tmean =

(Tend + Tmid)/2. For the values indicated

in Figures 6 and 7, this yields g = 9.787 m/s2;

which differs by one part per thousand from the value of 9.797 that was obtained

in a previous careful measurement of the earth's field in Macon, Ga [2].

Use of the sliding mass

As described in [2], the most accurate means for estimating g is to measure

the period of each of the two axes as a function of the position of the slider

that is pictured in Fig. 1. By means of a center punch during fabrication,

a set of 35 small-point indentations span the brass bar through nearly its

entire length. Beginning farthest from the end axis, these markers spaced

in 1 cm intervals would number 36, except that the mid axis hole disallows

the use of marker number 13.

For the present work, slider positions 8 through 17 were employed, yielding

the graph shown in Fig. 8.

Figure 8. Data used in estimating g with the highest accuracy. End

axis periods are represented by the blue diamonds and mid axis periods by

the red circles.

Each of the 18 period measurements performed for the generation of this figure

used a Lissajous figure generated by Excel, in which the pendulum was monitored

for a total decay time of 10 s. Using the quadratic trendline fit expressions

indicated in Fig. 8, Excel was used to find the period corresponding to the

intersection of the two curves. This period of 1.0007 s yields an estimate

for g of 9.801 m/s2, which differs from the Macon `standard'

by 5 parts per ten thousand. It is expected that the difference would become

smaller as more points should be used in the generation of Fig. 8.

Precision of the Lissajous measurement

As demonstrated in Fig. 9, the Lissajous technique is amenable to a parts

per ten thousand match of a theoretical fit to a record whose total length

is 10 s.

Figure 9. Representative example to illustration sensitivity to choice

for the theoretical value of pendulum frequency. Record length in all three

cases was the same 10 s, and all the indicated fit parameters were held constant

except for the frequency,.

It can be seen from Fig. 9 that `thickening' of the Lissajous `line' becomes

detectable if the frequency deviates from the best fit value by more than

two parts per ten thousand.

Use of Excel to generate the Lissajous figures

Excel can be readily configured with a template to rapidly generate the Lissajous

figures. Parameter adjustments by trial and error, that influence the graph

almost instantaneously, are configured for updates using `absolute' referencing.

A given raw data set is input to the template by means of paste operations

using hot keys. Selection of the Q is of least importance, followed by choice

of the amplitude parameter. These are selected most readily by also graphing

a time display of theory and experiment on the same plot. A rough setting

of phase and frequency are then also performed using the time plot. Once

a reasonably narrow line has been realized for the Lissajous curve, it is

then the only graph considered in the final selection for values of the phase

and frequency parameters. The technique used is similar to that of finding

the root of a function by jumping back and forth either side of the solution,

with ever smaller deviations from one choice to the next.

As noted earlier, the `best' estimate for a rapid determination of g, using

the Tel-Atomic Kater pendulum, is evidently the one which uses an average

involving (i) Eq. (8), and (ii) the mean value of the periods obtained from

the mid and end axes. The evidence for this claim is found in Fig. 10.

Figure 10. Comparison of g estimates based on two different methods,

with calculations using the same period values as the data graphed in Fig.

8. An x has been placed at the position corresponding to identical periods

of end axis and mid axix.

Over the full range of slider position from 8 to 17 cm, the method of Eq.(3)

is seen (in a global average sense) to provide a generally better estimate

for g than the method which works simply with the mean period of the two

axes. For a Kater pendulum with nearly matched periods the simple mean method

evidently gives comparable accuracy to the method using Eq.(3). Because of

the cusp in the plot of the latter, it is seen that the best approach is

to use the avereage of the two methods.

Noise level of the electronics

Because of the fully differential electronics, and the 24 bit adc electronics

package (21 bits employed in record saves), the signal to noise ratio of

measurements performed with this instrument is remarkably great. Its magnitude

is readily appreciated by comparing Fig. (7) with the next Fig. (11), which

was obtained after placing the pendulum on the pier of the seismic station

in the Mercer Physics department.

Figure 11. Electronics noise measured by placing the pendulum on a

seismic pier and providing a cover to eliminate air current disturbances.

For a max-amplitude value of 1,300,000 CDC counts and a noise floor of 182

CDC counts, we find an operational SNR > 7000.

Sensor Linearity

It is also noteworthy that the linearity of the sensor is excellent, as can

be seen from Fig. 12.

Figure 12. 4096-point FFT spectrum of an 88 s duration record obtained

using end axis oscillation. The amplitude of the motion was 865,000 CDC counts.

The pendulum's natural frequency is seen as the prominent spectral line at

1 Hz, and two of its harmonics are visible in the log-log plot. Harmonic

distortion is very low at -49 dB for the 2nd harmonic and -45 dB for the

3rd harmonic.

References

[1] described online

at

http://telatomic.com/mechanics/kater_pendulum.html

[2] R. D. Peters, ``Student-friendly precison pendulum'', The Physics Teacher,

37, Issue 7, p. 390 (1999).

[3] R. D. Peters, ``Study of simple harmonic oscillator resonance using a

compact Kater pendulum'', online at

http://physics.mercer.edu/hpage/kater-res.html

[4] R. D. Peters, ``Automated Kater Pendulum'', Eur. J. Phys. 18 (1997) 217-221.

Online at

http://iopscience.iop.org/0143-0807/18/3/016/pdf/0143-0807_18_3_016.pdf

[5]``Symmetric differential capacitance transducer employing cross coupled

conductive plates to form equipotential pairs'', U. S. Patent 5,461,319.

The predecessor LRDC sensor, also invented by Peters, was the first version

of ``fully differential capacitive sensors'', which are becoming increasingly

commonplace in engineering applications.

[6] described online

at

http://telatomic.com/mechanics/cavendish_balance.html

[7] The amplitude dependence of Q for nonlinear damping is treated on page

20-52 of:

R. D. Peters, ``Damping Theory'', Vibration and Shock Handbook, CRC

Press, ed. Clarence W. de Silva (2005). The same material is also available

in Ch. 2 of Vibration Damping, Control and Design, CRC Press, (2007).

File translated from TEX by

TTH,

version 1.95.

On 3 May 2012, 17:49.